NBC 2016 Part 8/Subsection 5A covers the requirements for planning, design, installation, operation, maintenance and inspection of lifts

General Terms Relating to Lifts

LIFT (elevator) : Lift An appliance designed to transport persons or materials between two or more levels in a vertical or substantially vertical direction by means of a guided car. The word elevator is synonymously used for lift.

Dumb Waiter : A lift with a car which moves in guides in a vertical direction; has a net floor area not exceeding 1 m2. dumb waiter total inside height of 1.2 m, whether or not provided with fixed or removable shelves; has a capacity not exceeding 250 kg and is exclusively used for carrying materials and shall not carry any person.

Lift Pit : The space in the lift well below the level of the lowest lift landing served

Lift Landing : That’ portion of a building or structure used for discharge of passengers or goods or both into or from a lift car.

Rated Load (Lift) : The maximum load for which the lift car is designed and installed to carry safely at its rated speed.

Rated Speed (Lift) : The mean of the maximum speed attained by the lift car in the upward and downward direction with rated load in the lift car

MRL Lift : MRL Lift It do not have a fixed machine room on the top of the hoistway, instead the traction hoisting machine is installed either on the top side wall of the hoistway or on the bottom of the hoistway.

Intended use of lift : The number of lifts and their capacities (that is, load and speed) required for a given building shall be suitably decided to meet the intended requirement.

System performance : System performance criteria shall be based on building type (residential, commercial, hotel, hospital, etc)

Accessibility requirements : All lifts installed for public use shall meet the accessibility requirements in accordance with 13 of Part 3 Development Control Rules and General Building Requirements of the NBC-2016

Environmental conditions : Lifts directly exposed to atmospheric conditions, that is, weather (for example, those meant for external applications), or any other adverse condition shall be appropriately designed and protected for that particular condition.

Considerations for Selection of Lifts

Type of main drive for lift : Whether electric traction, geared or gearless or hydraulic depending on speed, stops/travel height and capacity requirement.

Civil engineering requirements : Machinery location that is, machinery to be located in machine room or machinery to be kept inside lift well thereby eliminating conventional machine room.

Seismic considerations : Whether the lift is to be protected against seismic forces or whether the lift is to be rescued to a landing on detection of earthquake or both.

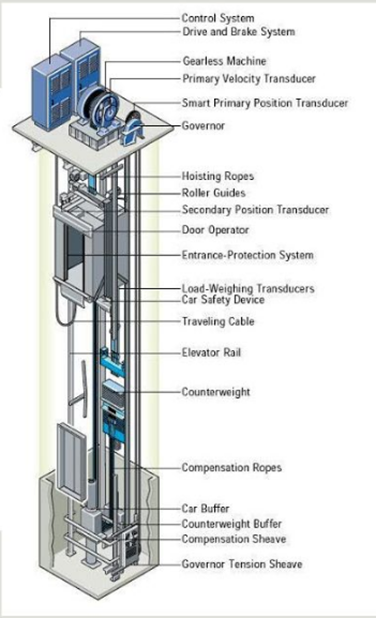

Types of Lift

Two types of lift

Traction (Electric) lift

- Virtually limitless rise (high & mid rise)

- High speeds, but high installation cost

Type of Traction lift

- Geared Traction

- Gearless Traction

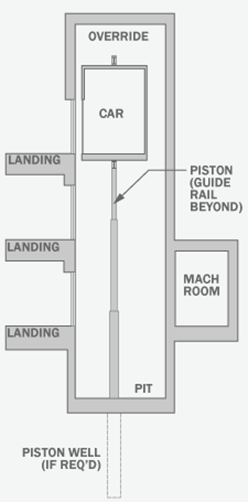

Hydraulic lift

- Limited to heights of about 60 ft. (6 stories)

- Lower speeds

- Lower initial cost – higher power consumption

Type of Hydraulic Lift

- Holed Hydraulic

- Holeless Hydraulic

- Roped Hydraulic

Geared Traction lift

Lift have a gearbox that is attached to the motor, which drives the wheel that moves the ropes. Geared traction lift are capable of travel speeds up to 500 feet per minute. The maximum travel distance for a geared traction elevator is around 250 feet.

Gearless Traction lift

Gear-less Traction Elevators have the wheel attached directly to the motor. Gear-less traction elevators are capable of speeds up to 2,000 feet per minute and they have a maximum travel distance of around 2,000 feet so they are the only choice for high-rise applications.

Geared traction elevators are middle of the road in terms of initial cost, ongoing maintenance costs, and energy consumption. Gear-less traction elevators have a high initial cost, medium ongoing maintenance costs, and use energy a bit more efficiently than geared traction elevators.

Hydraulic Elevator

Elevator are supported by a piston at the bottom of the elevator that pushes the elevator up as an electric motor forces oil or another hydraulic fluid into the piston.

The elevator descends as a valve releases the fluid from the piston. They are used for low-rise applications of 2-8 stories and travel at a maximum speed of 200 feet per minute. The machine room for hydraulic elevators is located at the lowest level adjacent to the elevator shaft.

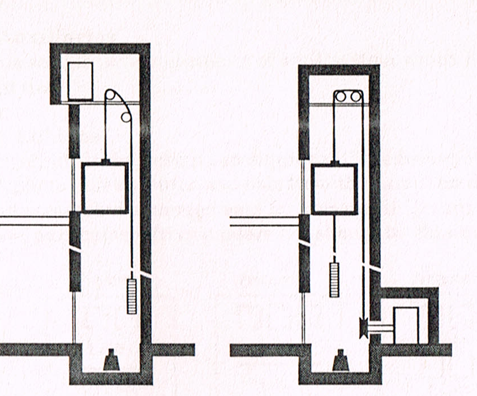

Bottom Drive Lift

For building up to about 8 floors the lift machine room may located at / below the lowest floor

- The system is for less then 8 floors

- The car speed is limited to 1m/s

- The lift machine create more noise in lift shaft

- More maintenance cost

- Vibration is more difficult to isolate from structure

- Impose greater load on structure

- The system cost is more

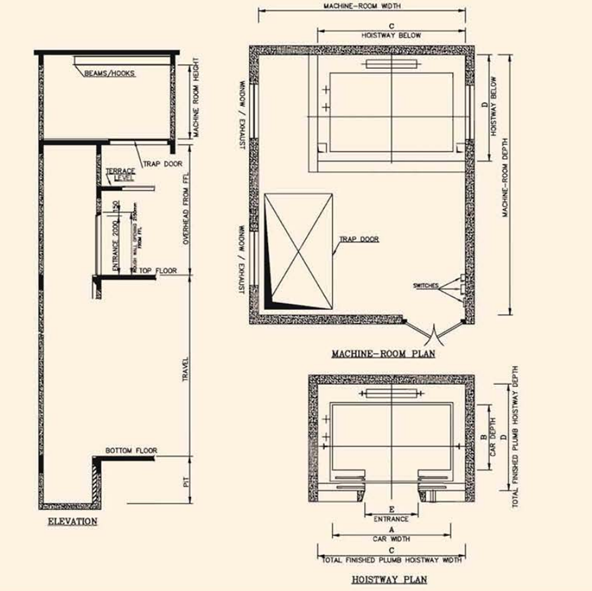

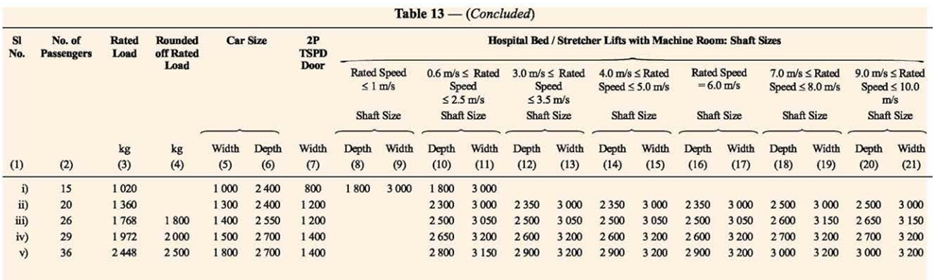

Recommended Dimensions of Passenger Lifts and Service Lifts

As per Clause 5.10.3.1 of section 5A of Part-8 of NBC 2016

The outline dimensions of lift shaft, machine room, pit depth, overhead and raw door opening size for lifts

NOTE

1 All dimensions given above for lifts having two panel telescopic doors (2P TSPD) with counterweight at side, are recommended dimensions primarily for architects and building planners. Any variations mutually agreed to between the manufacturer and the purchaser are permitted. However, variation in:

a)car inside dimensions shall be within the maximum area limits specified in accordance with accepted standards [8-5A(6)].

b)entrance width on higher side is permitted.

c)entrance width on lower side is permitted up to 100 mm subject to minimum of 700 mm.

d)2 Car depth of 2 100 mm may be considered in residential/commercial buildings, where use of only ambulance stretcher is envisaged. The hoist-way depth maybe reduced accordingly.

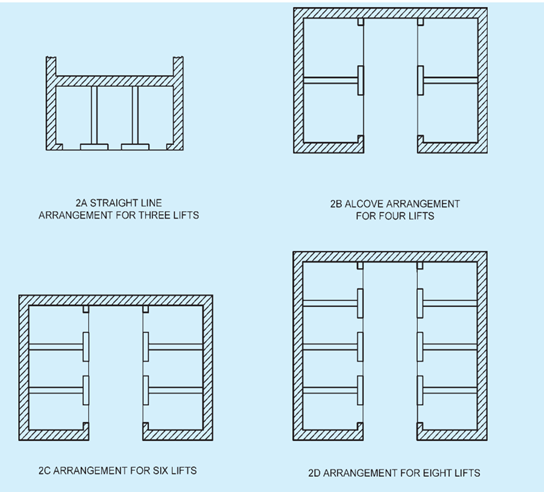

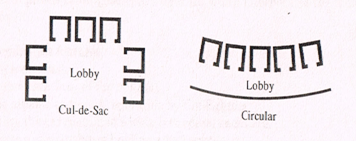

Grouping of lifts in high rise building

The lifts should be easily accessible from all entrances to the building. For maximum efficiency, they should be grouped near the centre of the building. It is preferable not to have all the lifts out in straight line and, if possible, not more than four lifts should be arranged in this manner. If more than 4 lifts have to be grouped together in a straight line, then destination control systems would require to adopted. Further, the corridor should be wide enough to allow sufficient space for waiting passengers as well as for through passengers

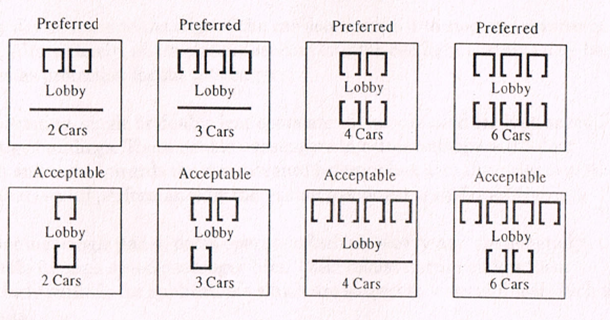

Lift lobbies

•All obstruction to traffic flow , particularly from passers-by , should be eliminated

•Cleary visible Ground floor lift lobby from main entrance of the building

- Main entrance should not visible for passenger within the lift car. To ensure that car are not kept waiting

- Noise generated by lift machinery and cars should be considered in relation to sensitive areas

- Plan for service core and there is buffer zone between lift lobby and the occupied space

Terms Relating to Planning and Design of Lifts

Door Closing Time (tc ) Time period measured from the instant that car doors start to close until the doors are locked.

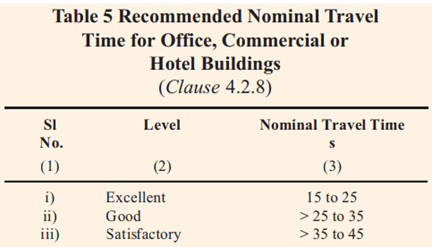

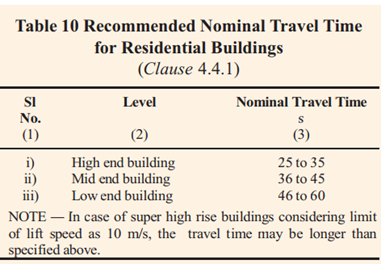

Nominal Travel Time (NTT) The nominal travel time is defined as the time it would take to run a distance of the total travel at the rated speed of the lift without taking into account the acceleration and deceleration of the car or the intermediate stops of real runs.

Passenger Average Waiting Time (AWT) Average period of time from the instant a passenger registers a landing call or joins a queue, until the responding lift begins to open its doors at the boarding floor.

Round Trip Time (RTT) The average time taken by a single lift to make a trip from the main terminal back to the main terminal, starting from the time the car doors open at the main terminal until the car doors re-open at the main terminal after serving all demand along the way.

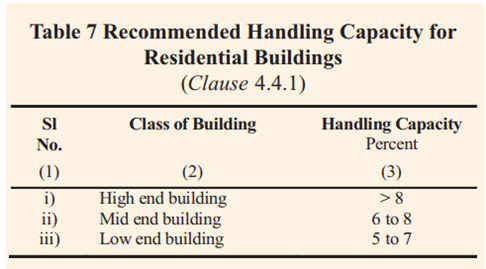

Handling Capacity (HC) The number of passengers that a lift system can theoretically transport during the up-peak traffic condition with car occupancy of 80 percent of the actual capacity expressed as a percent of the total building population.

Handling capacity

The handling capacity is calculated by the formula:

HC = (300 x Q x 100)/T x P

Where

HC = Handling capacity as the percentage of the peak population handled during 5 min.

Q = Average number of passengers carried in a car

T = waiting interval, and

P = Total population to be handled during peak morning period. (It is related to the area by a particular bank of lifts)

The value of ‘Q’ depends on the dimensions of the car. It may be noted that the capacity loaded always to its maximum capacity during each trip and, therefore, for calculate the value of ‘Q’ is taken as 80% of the maximum carry capacity of the car.

Waiting interval

The waiting interval is calculated by the formula :

T = RTT/N

Where,

T = waiting interval

N = number of lifts, and

RTT= round trip time

RTT is the sum of the time required in the following process :

a)Entry of the passengers on the ground floor,

b)Exit of the passengers on each floor of discharge,

c)Door closing time before each floor of discharge, TC

d)Door opening time on each discharging operation, TO

e)Acceleration periods,

f)Stopping and leveling periods,

g)Period of full rated speeds between stops going up, and

h)Period of full rated speeds between stops going down.

It is observed that the handling capacity is inversely proportional to the waiting time which in turn is proportional to RTT.

Recommended Nominal Travel Time (NTT)

As per Clause 4.2.8 of section 5A of Part-8 of NBC 2016 The recommended values for nominal travel time in case of an office, commercial or hotel building are given in Table 5 and Clause 4.2.8 Table 10 gives the nominal travel times of residential building

Installation requirements

Conformity with Lifts Act and Rules

The installation shall be carried out in conformity with Lift Acts and Rules, wherever they are in force. Like THE BOMBAY LIFT ACT, 1939, THE DELHI LIFT RULES, 1942 etc.

Conformity with The Electricity Act, 2003 and Rules/Regulations Thereunder

All electrical work in connection with installation of lifts shall be carried out in accordance with the provisions of The Indian Electricity Act, 2003

Conformity with Indian Standards

All materials, fittings, appliances, etc, used in electrical installation shall conform to Indian Standard specifications wherever these exist.

Conformity to Accessibility Requirements

All lifts installed for public use shall meet the accessibility requirements in accordance with 13 of Part 3 Development Control Rules and General Building Requirements of the NBC 2016

Conformity with Fire Regulations

The installation shall be carried out in conformity with Part 4 Fire and Life Safety of the NBC 2016 and the state fire acts/local fire regulations, wherever they are in force.

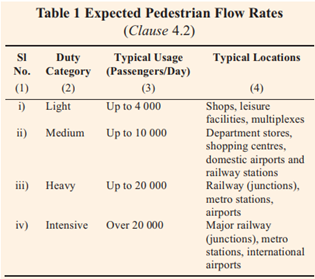

Escalators

Escalator — A power driven, inclined, continuous stairway used for raising or lowering passengers.

Named Escalator by Charles Seeberger in 1897 by combining the latin word for steps “scala” and elevator

Escalators are desirable where the movement of people are in large numbers at a controlled rate in the minimum of space for example, railway stations, shopping centres/malls, airports, etc. These encourage people to circulate freely and conveniently.

Inclination of 30º & 35º are common

Escalators Capacity

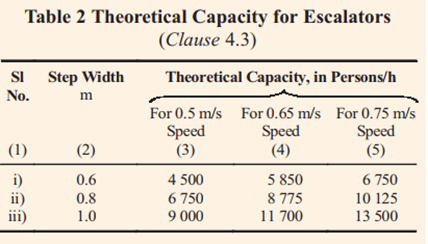

Theoretical Capacity for Escalators

The number of persons that may be theoretically carried by the escalators in 1 h is given in Table 2 in clause 4.3 of NBC 2017 P-8 Sec-5B

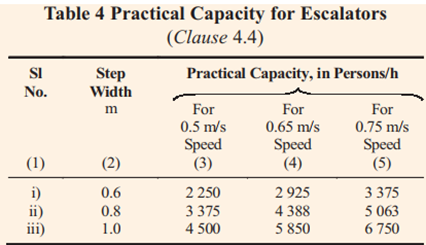

Practical Capacity for Escalators

The practical values should be considered while calculating the required number of escalators (based on traffic flow pattern). This practical capacity is given in table 4 in clause 4.4 of NBC 2017 P-8 Sec-5B

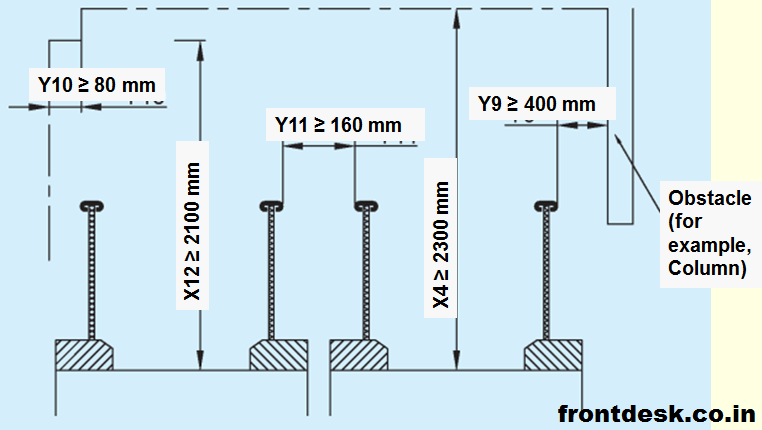

Free Space for Users

To prevent collision, a minimum free area around the escalator or moving walk is defined as per figure 4 of NBC 2017 P-8 Sec-5B

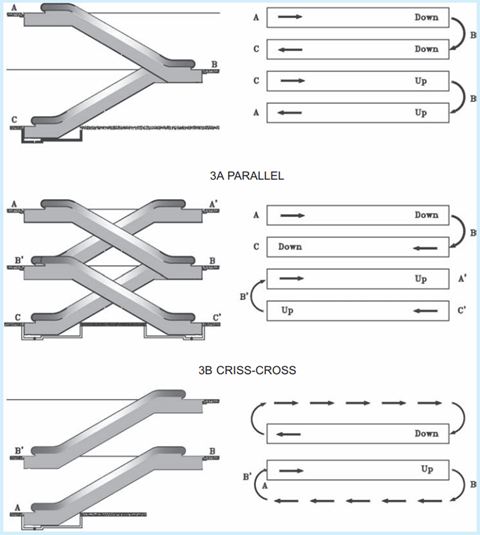

ESCALATOR CONFIGURATION

Escalators occupy more space than stairs in order to accommodate their inclination. There are few standard escalator arrangements as shown in Figure Type (a) and Type (b) provide efficient circulation by providing the shortest transition path and time from one escalator and the next.

Type (b) requires larger structural opening than Type (a) and Type (c) and present users with a higher risk of falling into the void.

Type (c) is typical of a store as it allows the store to lengthen the circulation route past goods for sale. This configuration also takes up free space

Indian Standards (IS CODE) for LIFTS

| IS CODE | Title |

| 14665 | Electric Traction Lifts |

| (Part 1) : 2000 | Guidelines for outline dimensions of passenger, goods, service and hospital lifts |

| (Part 2 / Sections 1and 2 ): 2000 | Code of practice for installation, operation and maintenance, Section 1 Passenger and goods lifts, Section 2 Service lifts |

| (Part 3 / Sections 1and 2) : 2000 | Safety rules, Section 1 Passenger and goods lifts, Section 2 Service lifts |

| (Part 4/ Sections 1 to 9) : 2001 | Components, Section 1 Lift buffers, Section 2 Lift guide rails and guide shoes, Section 3 Lift car frame, car, counterweight and suspension, Section 4 Lift safety gears and governors, Section 5 Lift retiring cam, Section 6 Lift doors and locking devices and contacts, Section 7 Lift machines and brakes, Section 8 Lift wire ropes, Section 9 Controller and operating device |

| (Part 5 : 1999) | Inspection manual |

Forum Threads

Register & Download PDF for Educational Purposes Only

Register as member and login to download attachment [pdf] by right-click the pdf link and Select “Save link as” use for Educational Purposes Only

Disclaimer

Information on this site is purely for education purpose. The materials used and displayed on the Sites, including text, photographs, graphics, illustrations and artwork, video, music and sound, and names, logos, IS Codes, are copyrighted items of respective owners. Front Desk is not responsible and liable for information shared above.