- FORUM

- PROJECTS

- ABOUT US

- RESOURCES

- CONTACT US

- FORUM

- PROJECTS

- ABOUT US

- RESOURCES

- CONTACT US

Wooden paneling and Staircase

Wooden paneling and Staircase

The most common use of wood paneling is for partitioning and for covering of large areas as the sheets generally come in large sizes and are extremely light and easy to work with. Wood panels are usually 4×8 foot in size. Wood paneling comes in four different types and depending on what you are using them for and what overall look you want you will want to research more on which is best for your type of installation:-

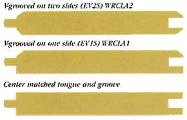

1. Tongue and Groove.

2. Overlap.

3. Shiplap Edges.

4. Plank Paneling.

Tongue and grove paneling

Tongue and grove is the most popular because it is easy to install and transport.

Overlap paneling

Shiplap joints paneling

Shiplap joints paneling are formed by cutting identical rabbets into opposite faces of adjoining boards. This produces a joint where the rabbets overlap, preventing gaps between the boards from being visible.

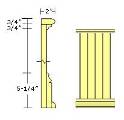

Plank Paneling

plank paneling is composed of a series of planks that line the wall from floor to ceiling. You can choose planks that run vertically or horizontally, though a vertical application is most common. The width of the planks varies, so you can choose the size that best fits the scale of your room.

Beadboard or Wainscot paneling

Beadboard is a very popular decorative paneling option and is often used in wainscoting which is when paneling is placed on the lower half of walls. This practice was extremely popular in colonial times and is still very popular today. which deals well with varied weather conditions.

Wood Veneer Panels.

The veneer finish panels consist of three plies. Pre-finished are the most expensive types and those with grains will achieve the best quality.

Vinyl Coated Panels.

Vinyl coated panels generally have a design that has been laminated into plywood. They are easy to clean but scratch easily. Although the overall look is often very similar to wood, they do require special cleaning agents in order to prevent damage.

Bamboo Paneling

Due to its durability and the fact that it is highly sustainable and is harvested and produced in a range of countries around the world, it is growing in favour. The rich colors make it a wonderful addition to walls, ceilings and floors and can even be used as an exterior cladding option.

Wood for Staircase

Pine, poplar, oak, maple, and cherry are the most popular wood for staircase construction

Pine– Southern Yellow Pine is the most common material used to make stairs be cause of its strength and cost. Because it is economical, there are several grades of this wood.

Poplar– Color variation and distinctive graining is common in poplar. However, it accepts paint well and is nearly clear. Because of these characteristics, poplar is commonly used in painted or carpeted stairs. It is the least expensive of the hardwoods.

Hardwoods-Oak, Cherry, and Maple are the most popular types of hardwoods. When stairs are made out of these materials, they are considered to be “finish grade.” It is expected that the stairs will be viewed as a showpiece in the room and the wood must be of exceptional quality. Because of this, only wood with knots and flaws up to 1/8” in size are accepted.

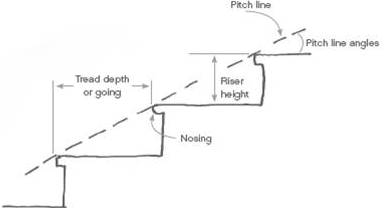

The three main parts of a staircase are :

Tread– The part of the staircase, horizontal to the floor, that a person steps on while walking between floors. Usually has a bull nose edge finish.

Riser– Risers work as a backing to the tread to keep the foot from traveling past the edge of the tread. They are vertical to floor.

Stringer– The purpose of the stringer is to contain both the tread and the riser and provide structure to the staircase. This component runs at a diagonal from floor to floor.

Types of Staircases

There are 6 standard stair types that are used in most practical applications. Custom designed stairs are also available to showcase the unique décor of your home.

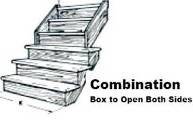

Box – A complete boxed in stair with housed stringers on both sides. On this stairway, the ends of each tread and riser are installed into recessed stringer routings creating a box appearance.

Open 1 Side– One side of these stairs is closed or boxed in. The opposite side is open with all returned end treads. On the open side, the wall usually runs underneath the stringer for support. These stairs are considered to be more decorative than the box type because the balusters will run directly into the treads.

Open 2 Sides– A decorative stair design, each tread is mitered and open on both sides. There is not a boxed in section anywhere on this stair type. Walls typically run beneath both sides of this stair.

Combination– These stairs have both boxed in and open sections. The amount of returned end open treads is determined by location of the finished wall line. This configuration is common when the stairs run against a wall and then into an open room.

Platform – Multiple sets of stairs that meet on a landing to meet space limitations and accommodate room layout. They are made up of 2 sets of stairs, boxed, open, or combination.

Circular/Curved – Any of the above designs can be made in a curved staircase. On this type the treads are slightly pie shaped. The shape causes the staircase to have a radius.

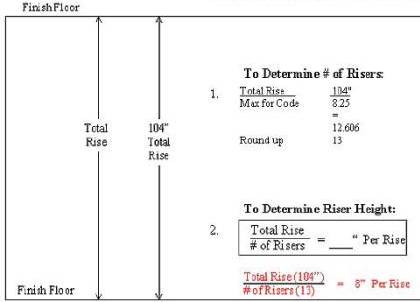

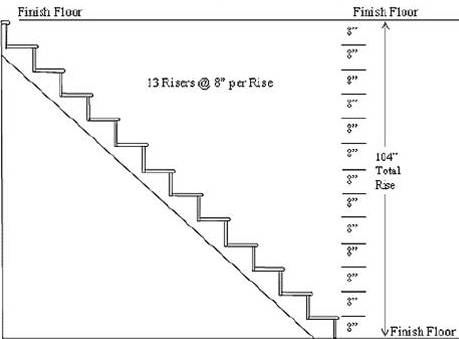

Determining Rise of Staircases

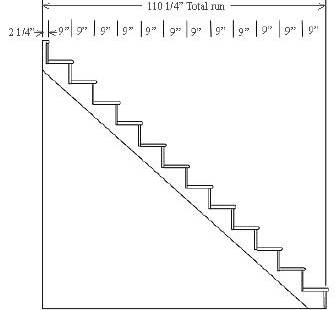

Determining Run of Staircases

In a straight staircase, there will always be one fewer stair tread than riser. This is to account for the additional rise needed to meet up with the top floor. Using this rule of thumb to refer back to the previous example of the 104” floor to floor 13 rise staircase, there will be 12 treads.

Interior Wooden Staircase

A stringer that closes off the ends of the treads and risers is a closed stringer. If the stair is built between walls the stringer may be called a wall stringer. In this case the stringer is attached to the wall and transfers the stair load directly to the wall. It is generally sized to accommodate the tread and riser, and align with skirtings.

Interior timber stairs can be constructed as shown in Figures Solid timber or medium density fibreboard sheet (MDF) may be used in the construction. MDF is normally used for treads and risers. It is glued and screwed while solid timber may be nailed and screwed.

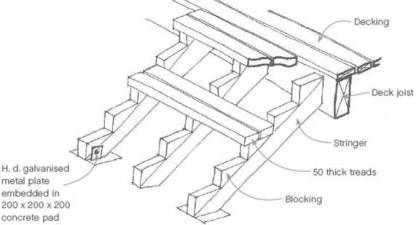

Exterior Wooden Staircase

A simple form of stair can be constructed from solid timber to provide access to exterior deck areas.

The treads can be attached to the stringers with by 50 x 50 mm brackets. The stair timber and fixings used should meet the same durability requirements as the deck construction. Exposed bolts and other fastenings will need to be type 316 stainless steel or epoxy coated hot-dip galvanised steel.

Timber treads need to be coated with a non-slip finish or grooved to provide a slip resistant surface.

Balustrades and handrails will be needed if a fall greater than one metre is possible.

Open treads that have a gap of more than 100 mm between treads are not suitable where the stair may be accessed by the public, e.g. the front steps to a house.

Layout of stairs, handrails and balustrades

Advantage/ Disadvantage of Wooden Staircase

Advantages

- • Allows paddlers easier access from a steep or eroding shoreline

- • Aesthetically pleasing; less disruptive to “natural” shoreline than concrete

- • May be easily and inexpensively repaired, if damaged

Disadvantages

- • Installation may be costly and may require alteration to shoreline

- • May be susceptible to undercutting

- • May require maintenance as stairs age and weather

Disclaimer: All the diagrams and sketches are copyrighted items of respective owners. . They are provided here just for refrence/information.

Forum Threads

For your views and discussions Register in FDAchitects Forum …