- FORUM

- PROJECTS

- ABOUT US

- RESOURCES

- CONTACT US

- FORUM

- PROJECTS

- ABOUT US

- RESOURCES

- CONTACT US

Fine and Coarse Aggregates

Fine and Coarse Aggregates

For a good concrete mix, aggregates need to be clean, hard, strong particles free of absorbed chemicals or coatings of clay and other fine materials that could cause the deterioration of concrete. Aggregates, which account for 60 to 75 percent of the total volume of concrete, are divided into two distinct categories–fine and coarse. Fine aggregates generally consist of natural sand or crushed stone with most particles passing through a 3/8-inch sieve. Coarse aggregates are any particles greater than 0.19 inch, but generally range between 3/8 and 1.5 inches in diameter. Gravels constitute the majority of coarse aggregate used in concrete with crushed stone making up most of the remainder.

Characteristics of Aggregates

- Grading

- Durability

- Particle shape and surface texture

- Abrasion and skid resistance

- Absorption and surface moisture

- Unit weights and voids

Grading

Grading is the distribution of particles of angular materials among various sizes. Grading is usually expressed in terms of cumulative percentage passing each sieve.

Different standards and specifications specify grading limits for both fine and coarse aggregates. There are several reasons for specifying grading limits and maximum aggregate size, they affect relative:

Relative aggregate proportionsCement and water requirementWorkabilityPump abilityEconomyShrinkage and durability of concrete

Fineness Modulus

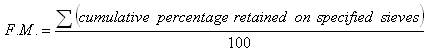

The fineness modulus (FM) for both fine and coarse aggregates is obtained by adding the cumulative percentages by mass retained on each of a specified series of sieves and dividing the sum by 100.The FM is an index of the fineness of the aggregate. The higher the FM, the coarser the aggregate. FM of fine aggregate is useful in estimating proportions of fine and coarse aggregate in concrete mixtures.

Particle Shape and Surface Texture

The shape and surface texture affect the properties of fresh concrete more than the properties of hardened concrete.Rough-texture, and angular particles require more water to produce workable concrete than do smooth, rounded and compact particles. For both crushed or noncrushed aggregate, proper gradation gives the same strength for the same cement factor.Bond between cement paste and a given aggregate generally increases the particles surfaces change from smooth and rounded to rough and angular. The increase in bond is important for selecting aggregates for concrete where strength at early age is important.Aggregate should be free of flat or elongated particles. Because they require an increase in mixing water and thus may affect the strength of concrete particularly in flexure.

Absorption and surface moisture

Absorption and surface moisture of aggregate are measured when selecting aggregate because the internal structure of aggregate is made up of solid material and voids that may or may not contain water. The amount of water in the concrete mixture must be adjusted to include the moisture conditions of the aggregate.

Abrasion and skid resistance

Abrasion and skid resistance of an aggregate are essential when the aggregate is to be used in concrete constantly subject to abrasion as in heavy-duty floors or pavements. Different minerals in the aggregate wear and polish at different rates. Harder aggregate can be selected in highly abrasive conditions to minimize wear.

M Sand & P Sand IS Specification

Grading Limits for Grit (Rodi)

FD Forum Threads

Disclaimer

Information on this site is purely for education purpose. The materials used and displayed on the Sites, including text, photographs, graphics, illustrations and artwork, video, music and sound, and names, logos, IS Codes, are copyrighted items of respective owners. Front Desk is not responsible and liable for information shared above.