- FORUM

- PROJECTS

- ABOUT US

- RESOURCES

- CONTACT US

- FORUM

- PROJECTS

- ABOUT US

- RESOURCES

- CONTACT US

Aim : To improve the raw water quality to the drinking water standards and stop water borne transmission of epidemics .

Methods of treatment :

Depends on the nature of source and its water quality .

Subsurface source Generally Chlorination will be sufficient except where iron is present .

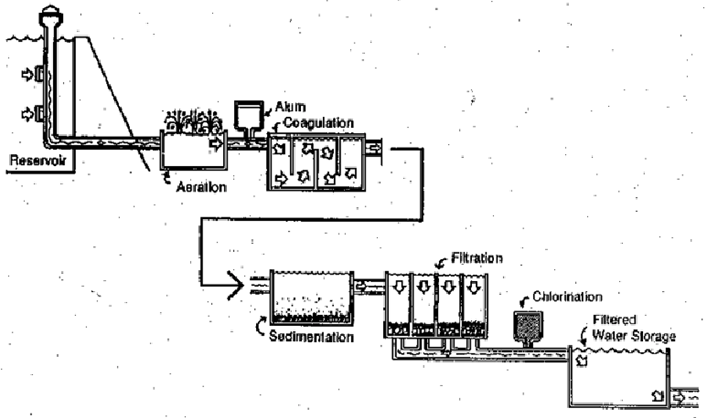

Surface source : 1.Aeration ( if required) 2.Pre chlorination ( optional ) 3.Sedimentation – either plain or with coagulation and flocculation , 4.post chlorination ●

1. Aeration

Aim : i.to remove objectionable tastes and odours . ii.for expulsion of carbon dioxide, hydrogen sulphide . iii.to precipitate impurities iron and manganese present. iv.For increasing the dissolved oxygen content to water for imparting freshness.

Types of aeration i.Spray – Type ii.Multiple tray or water fall iii.Cascade type iv.Diffused air aerators v.Mechanical aerators

2. Pre – Chlorination

Aim : i.to prevent biological growth in raw water ii.for reduction of colour . iii.for destruction of some taste & odour producing compounds . iv. for oxidation of iron, manganese and hydrogen sulphide . v.to aid coagulation. vi.for minimizing post-chlorination dosage .

Dosage : 1 to 5 ppm depending on the degree of pollution .

3. Plain Sedimentation

Aim : To separate suspended impurities from water by gravitation .

Detention period : One to several days for sedimentation without subsequent filtration to 4 hours for sedimentation in conjunction with filters .( much longer settling time for basins preceding slow sand filters than for rapid sand filters ) .

Loading rate: 2.4 to 24m3 / day / m2

4 Chemical dosing

Aim : i.For coagulation, flocculation . ii.disinfection and softening . iii.algal and corrosion control . iv.for fluoridisation .

Types :

(i) Dry feed .

(ii) Solution feed .

Strength of solution :To be not more than 5% for manual feed and not more than 10% for mechanical feed.

Alum is the most common coagulant used and economical.

Lime is also added when PH and alkalinity are low

Dosage for alum : 20-100 mg / 1 (1-5 grain / gallon )

Dosage for lime: About one third that of alum

Density of lime = 670 kg / m3 , Density of alum = 980 kg / m3

5. Flash mixing

Aim : To disperse the coagulant evenly in the water.

Generally used when flow exceeds 300 Cu.m / hour.

Head loss : 0.20 – 0.60 m of water

Ratio of tank dia. To height : 1.1 to 3.0

6. Coagulation and Flocculation

Aim :The addition of a coagulant like alum promotes the formation of micro floes which are the nuclei for the absorption of turbidity and colour causing particles.

During flocculation, the micro floc particles formed during rapid mixing are brought together to aggregate into larger rapidly settle able floes by controlled agitation of water .

Detention Period :15-30 minutes in flocculation zone .2-3 hours in settling or clarifier zone . Dosage :To be decided by Jar Test .

Coagulation: colloidal destabilization

•Typically, add alum (aluminum sulfate) or ferric chloride or sulfate to the water with rapid mixing and controlled pH conditions

•Insoluble aluminum or ferric hydroxide and aluminum or iron hydroxo complexes form

•These complexes entrap and adsorb suspended particulate and colloidal material.

Flocculation: Slow mixing (flocculation) that provides for for a period of time to promote the aggregation and growth of the insoluble particles (flocs).

The particles collide, stick together abd grow larger

The resulting large floc particles are subsequently removed by gravity sedimentation (or direct filtration) Smaller floc particles are too small to settle and are removed by filtration

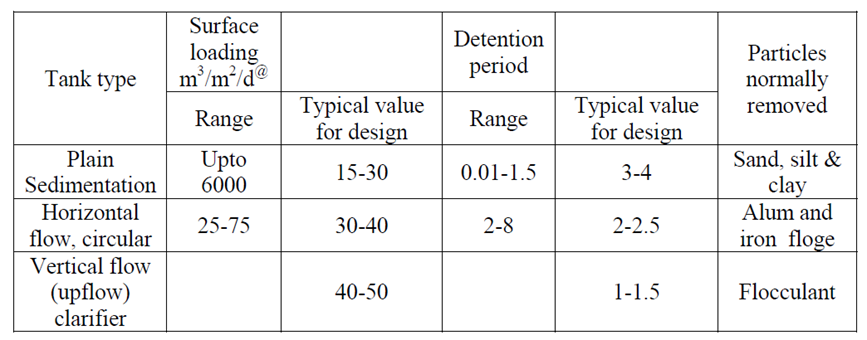

7. Sedimentation

Aim: To remove readily settling sediments such as sand, silt, coagulated impurities such as colour and turbidity and precipated

The range of surface loadings and detention periods for average design flow for different types of sedimentation tanks are as follows:

8. Filtration

Aim i. to separate the suspended and colloidal impurities in the water .

ii. to produce sparkling and aesthetically attractive water free from disease

producing organism .

Types :

a. Slow Sand Filters : Slow sand filters can provide a single step treated for 46 polluted surface waters of low turbiding (< 20 Ntu)

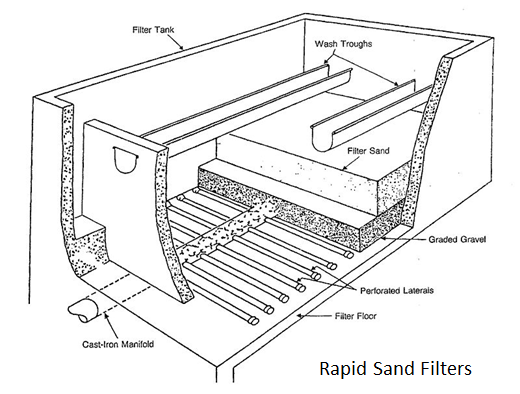

b. Rapid Sand Filters : The rapid sand filter comprises of a bed of sand serving as a single medium granular matrix supported on gravel overlaying an under drainage system.

Turbidity is measured in NTU: Nephelometric Turbidity Units. The instrument used for measuring it is called nephelometer or turbidimeter, which measures the intensity of light scattered at 90 degrees as a beam of light passes through a water sample.

Rapid sand filtration is a purely physical drinking water purification method. Rapid sand filters (RSF) provide rapid and efficient removal of relatively large suspended particles.

Two types of RSF are typically used: rapid gravity and rapid pressure sand filters. For the provision of safe drinking water, RSFs require adequate pre- treatment (usually coagulation-flocculation) and post- treatment (usually disinfection with chlorine). Both construction and operation is cost-intensive. It is a relatively sophisticated process usually requiring power-operated pumps, regular backwashing or cleaning, and flow control of the filter outlet.

Rapid sand filtration is common in developed countries for the treatment of large quantities of water where land is a strongly limiting factor, and where material, skilled labour, and continuous energy supply are available. The major parts of a gravity rapid sand filter are:

1.Chamber: filter tank or filter box

2.Filter media (sand)

3.Gravel support

4.Under drain system

5.Wash water troughs.

Slow sand filters

Slow sand filters may be used where there is sufficient land and space, as the water must be passed very slowly through the filters. These filters rely on biological treatment processes for their action rather than physical filtration

Membrane Filtration

Membrane types & example full-scale configurations:

•Microfiltration ~ 0.1 to 100 μm

•Ultrafiltration ~ 0.005 to 10 μm

•Nanofiltration ~ 0.5 nm to 1 μm

Highly effective particle removal

•Reverse osmosis ~ 0.01 nm to 0.1 μm

Dissolved contaminant removal

9. Wash water Gutter :

Horizontal travel of dirty water over the surface of filter shall not be more than 0.6 to 1.0 m before reaching the gutter .

Bottom of gutter should clear the top of Expanded sand by 50 mm or more .

Upper edge of gutter should be placed as far above the surface of the undisturbed sand surface as the wash water rises in 1 minute .

10. Back wash .

Back wash should be arranged at such a pressure that the sand expands to about 130 to 150 of its undisturbed volume or 5 m head of water as measured in under

drain. Normally the wash water is applied at 36 m (600 lpm/m2) for a period of 10 minutes

11.Pressure Filters

Same principle as gravity type rapid sand filters; but water is passed through the filters under pressure. Tank axis may be vertical or horizontal.

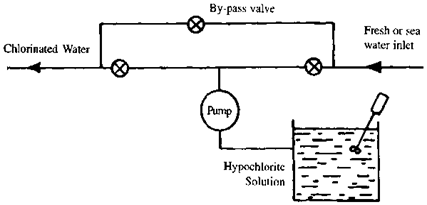

12.Post Chlorination :

Aim : For disinfection of potable water by the use of gaseous chlorine or chlorine compounds to destroy bacteria through the germicidal effects of effects of chlorine; may be done at head works / treatment works and supplemented by additional chlorination in loose pockets of distribution system.

Dosage: When prechlorination is adopted relatively small doses will be required generally 1 to 2mg/l.

Often the most critical step in protection of consumer against pathogenic microorganisms : organisms are killed (or “inactivated”) by reaction with various chemical oxidants.

Commonly-used disinfectants: •“Free” chlorine – Applied as Cl2(g) or NaOCl (HOCl is the active disinfectant in either case) •Chloramines, or “Combined” chlorine – Applied either as pre-formed NH2Cl, or by mixing NH3 and HOCl •Chlorine dioxide – Applied as ClO2(g) •Ozone – Applied as O3(g) (no long-term residual) •Ultraviolet light – Applied via submerged UV lamps (no residual)

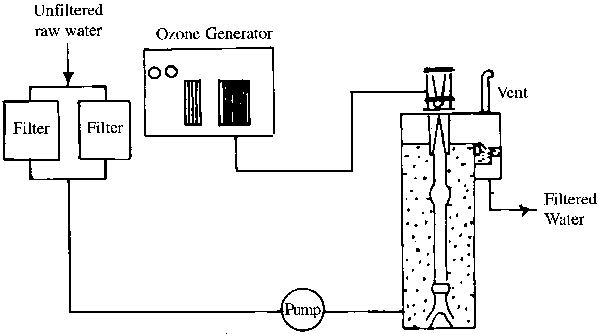

Ozone treatment

Though the principle is relatively simple, this method needs special equipment, supply of pure oxygen and trained operators. Ozone is generated by passing pure oxygen through an ozone generator. It is then bubbled through a gas diffuser at the bottom of an absorption column, in a direction opposite to the flow of raw water. Retention or contact time is critical and the size of the absorption column depends on the water flow.

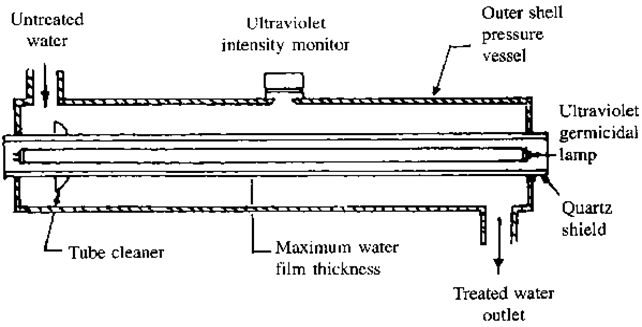

Ultraviolet irradiation treatment

This method is often used to treat drinking water. Successful commercial installations have been made to purify sea water in large fish processing plants.

· U-V rays in the range of 2500-2600 Angstrom units are lethal to all types of bacteria.

· There is no organoleptic, chemical or physical change to the water quality.

· Overexposure does not have any ill effects.

Register & Download PDF for Educational Purposes Only

Urban Infrastructure and Network Study notes for M. plan Sem-III

Urban Infrastructures & Network.pdf

Register as member and login to download attachment [pdf] by right-click the pdf link and Select “Save link as” use for Educational Purposes Only

Disclaimer

Information on this site is purely for education purpose. The materials used and displayed on the Sites, including text, photographs, graphics, illustrations and artwork, video, music and sound, and names, logos, IS Codes, are copyrighted items of respective owners. Front Desk is not responsible and liable for information shared above.