- FORUM

- PROJECTS

- ABOUT US

- RESOURCES

- CONTACT US

- FORUM

- PROJECTS

- ABOUT US

- RESOURCES

- CONTACT US

Thermal and Acoustic Insulation

Thermal insulation is the reduction of heat transfer between objects in thermal contact or in range of radiative influence.

Acoustic Insulation is any means of reducing the intensity of sound with respect to a specified source and receptor.

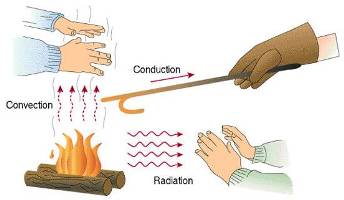

How Heat Is Transmitted

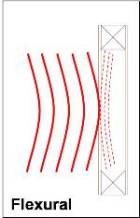

Conduction: the transmission of heat from one molecule to another within a material or from one material to another when they are held in direct contact.

Convection: the transfer of heat by another agent, such as air or water. Convection Currents: the flow of air that is created within the space.

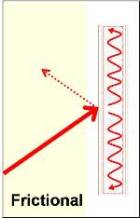

Radiation: the transmission of heat through a wave motion, similar to the way light is transmitted.

Thermal Insulation Facts

Fibrous materials are generally good insulators

Commercial insulation materials are made of:

- Glass fibers

- Glass foam

- Mineral fibers

- Organic fibers

- Foamed plastic

Characteristics of a good insulation material:

- Fireproof

- Insect proof

- Moisture proof

- Resistant to any physical change that would reduce its effectiveness against heat flow

Selection of insulation is based on:

- Initial cost

- Effectiveness

- Durability

- Adaptation of its form to that of the construction and installation methods

Heat Loss Coefficients

British Thermal Unit: Btu, the amount of heat needed to raise the temperature of 1 pound of water to 1 degree Fahrenheit.

Coefficient of Thermal Conductivity: k, the amount of heat, in Btu’s, transferred in one hour through 1 sq. ft. of a given material that is 1” thick and has a temperature difference between its surfaces of 1 degree Fahrenheit.

Conductance: C, the amount of heat that will flow through the material in 1 hour / sq. ft. of surface with a 1 degree Fahrenheit of temperature difference.

Resistance: R, the opposite of conductivity or conductance. A good insulation material will have a high R- value.

Total Heat Transmission: U, represents in Btu / sq. ft. / hour with 1 degree temperature difference for a structure which may consist of several materials or spaces.

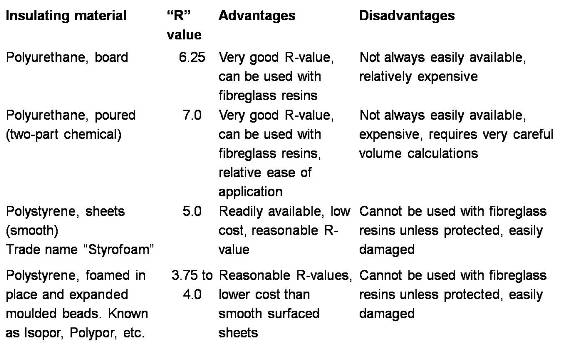

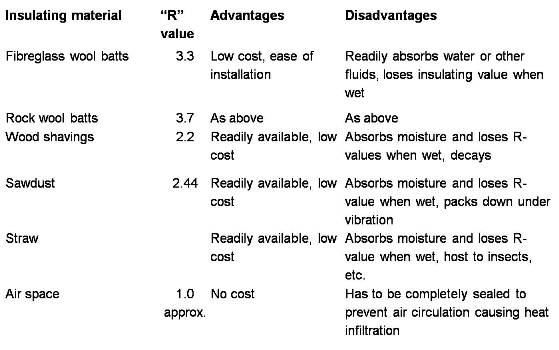

Common insulating materials, “R” values per inch , advantages and disadvantages

Spray Polyurethane Foam (SPF) Insulation

A two component mixture comes together at the tip of a gun, and forms an expanding foam that is sprayed onto concrete slabs, into wall cavities of an unfinished wall, against the interior side of sheathing, or through holes drilled in sheathing or drywall into the wall cavity of a finished wall.

sometimes also called Foamed-In-Place Insulation

Rigid panels/Insulation

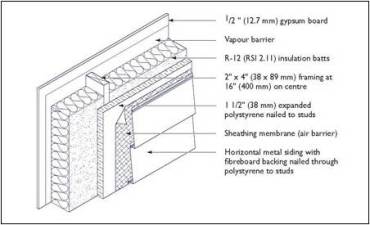

Rigid panel insulation is made from fibrous materials (fiberglass, rock and slag wool) or from plastic foam. They are sometimes sold in sections designed to fit tightly in standard wall cavities.

Rigid polyurethane / Polyisocyanurate (PUR/PIR) foam

Rigid polyurethane foam (PUR/PIR) is a closed-cell plastic. It is used as factory made thermal insulation material in the form of insulation boards or block foam, and in combination with various rigid facings as a constructional material or sandwich panel. Polyurethane in-situ foams are manufactured directly on the building site.

Molded Expanded Polystyrene (MEPS) / Extruded Expanded Polystyrene (XEPS) Foam Board

Polystyrene pellets are mixed with various chemicals to liquefy them. A blowing agent is then injected into the mixture, forming gas bubbles, which produce a closed-cell material that are then molded into large sheets. Commonly known as beadboard, it has an R-value of about 4 per inch of thickness.

(XEPS) Foam Board Extruded expanded polystyrene insulation is similar to MEPS, but the foaming, thick liquid is forced through a shaping die.

Insulated Concrete Forms( ICF)

ICFs are hollow, light-weight “stay in place” forms made of two Expanded Polystyrene (EPS) panels which are connected by polypropylene webs. During construction, the forms are stacked to the desired height then filled with concrete making stable, durable and sustainable walls.

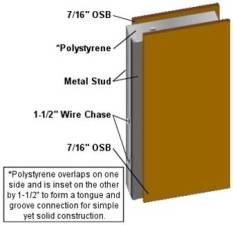

Structural insulated panels( SIP)

Structural insulated panels (SIPs), also called stressed-skin walls, use the same concept as in foam-core external doors, but extend the concept to the entire house. They can be used for ceilings, floors, walls, and roofs.

The panels usually consist of plywood, OSB, sandwiched around a core of expanded polystyrene, polyurethane, polyisocyanurate, compressed wheat straw, or epoxy.

Oriented strand board, ( OSB)

Oriented strand board, (OSB) or Sterling board (UK), is an engineered wood product formed by layering strands (flakes) of wood in specific orientations.

Blanket Insulation

– made from fibrous materials like mineral wool, wood fiber, cotton fiber or animal hair and manufactured to form a mat with thickness of ½” – 4 “ .

Some installed with vinyl cardboard or wire mesh and is stapled to sides and edges of studs and joists.

Batt Insulation

Batts are precut, whereas blankets are available in continuous rolls.

Components of Batt and Blanket Insulation

Fiberglass is a material made from extremely fine fibers of glass. Made from molten glass, usually with 20% to 30% recycled industrial waste and post-consumer content.

Rock and slag wool. Usually made from rock (basalt, diabase) or iron ore blast furnace slag. Some rock wool contains recycled glass. Nonflammable.

Loose Fill

Cellulose is 100% natural and 75-85% of it is made from recycled newsprint.

Fibrous Insulation from mineral wool rock, glass wool, slag wool or vegetable fiber usually of wood fiber.

Granular Insulation from expanded minerals like perlite, vermiculite or ground vegetable matter.

Reflective Insulation

Consists of 2 layers of 99% aluminum foil laminated to the outsides of 2 sheets of heavy-duty polyethylene air-bubble cushioning.

Corrugated Insulation

From paper formed into shapes that produced enclosed air pockets into small regular semi – circular corrugations and covering both sides with sheet of flat paper to give strength and produce the air pockets.

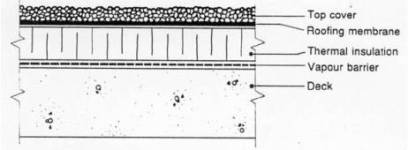

Thermal Insulation

Can be installed in THREE positions:

- BELOW the deck

- BETWEEN the deck and the membrane

- ABOVE the membrane

Flat Roof: Insulation and Membrane Position

A vented air space is mandatory when using batt insulation in a flat roof!! If you use rigid polystyrene insulation (the blue kind), no air space is necessary as it is waterproof.

Insulation BETWEEN the Deck and the Membrane

Traditional location for insulation:

use low density rigid panels to support the loads on the roof membrane without allowing puncture of membrane

any water vapour trapped in insulation will cause deck to rot so use topside vents to relieve pressure

Insulation ABOVE the Membrane

New concept offering major advantages:

- membrane protected from extremes of heat and cold, is on the warm side of the insulation

- membrane protected from UV radiation

- membrane protected from puncture

- insulation must be extruded polystryrene foam board which is water resistant and covered with a filter layer to prevent migration of ballast

Vapour Retarders for Low Slope Roofs

- membrane in a protected membrane roof is also the vapour/air barrier

- other types of low slope roofs use two layers of asphalt saturated roofing felt bonded together and to the roof with hot asphalt

- polyethylene film not used as it melts

- situated on the warm side of the insulation

Acoustic Insulation (Soundproofing)

Is any means of reducing the intensity of sound with respect to a specified source and receptor.

Soundproofing affects sound in two different ways: Noise Reduction and Noise Absorption.

Methods Of Absorption

Acoustical Materials

General Classifications:

- Porous Materials

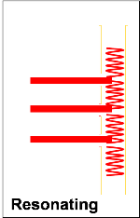

- Panel or Membrane Absorbers

- Cavity (Helmholtz) Resonators

Porous Materials

Soft, porous materials are very good sound absorbers. The basic acoustical characteristic of these materials is a cellular network of interlocking pores. Within these pores, incident sound energy is converted into heat.

Examples of these include acoustical boards, diffusers, soft plasters, mineral wool, and acoustical blankets, among others.

Characteristics:

Their sound absorption is more efficient at high, rather than low frequencies. However, their acoustical efficiency improves in the low frequency range with increased thickness and with distance to their solid backing.

Categories of Commercial Materials:

Pre-fabricated Acoustical Units

Various types of perforated, fissured, or textured materials constitute typical units in this group.

Commonly used materials include:

- Acoustical Boards

- Acoustic Hangers

- Geocoustic Tiles

- Diffusers

Acoustical Boards

These can be installed in several ways:

- Cemented to a solid backing

- Nailed or screwed to wood framing

- Laid in a ceiling suspension system

Advantages

- Trade catalogs contain detailed specifications

- Easy installation and maintenance

- Flexible absorption

Disadvantages

- Difficult to conceal joints between units

- Soft structure subject to damage

- Paint redecoration harmful to absorption

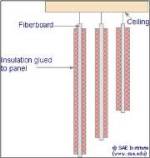

Acoustic Hangers

Acoustic Hangers or baffles- a system of fiber-board panels that are wrapped with insulation and are hung freely using wire or rope.

Geocoustic Tiles And Panels

Geocoustic Tiles- special prefabricated units for random application on walls and ceilings.

Diffusers

Diffusers- absorptive material that have, irregular surfaces, or angled or curved fronts, so when mounted on a wall or the ceiling they stop parallel wall interference and prevent standing waves.

Acoustical Terms

Sound: a vibration or wave motion that can be heard, reaches the ear through air, the air vibrates back and forth in tiny molecular motions of high and low pressure

Decibel: the unit of measurement used to indicate the loudness or intensity of sound; comparable to the “degree” as a measurement of heat or cold

Reverberation Sounds: airborne sounds which continue after the actual source has ceased, caused by reflections from floors, walls and ceilings

Frequency: rate at which sound energized air molecules vibrate

Impact Sounds: sounds that are carried through the building by the vibrations of the structural materials themselves

Masking Sounds: normal sounds within habitable rooms which tend to “mask” some of the external sounds entering the room

Decibels Reduction: expression used to indicate the sound insulating properties of a wall or floor panel

Sound Transmission Loss: STL, the number of decibels which sound loses when transmitted through a wall or floor

Sound Absorption: capacity of a material or object to reduce sound waves by absorbing them, these sounds are otherwise reflected and cause excessive reverberation and build up of intensity within that area

Noise Reduction Coefficient: NRC, the sound absorption of acoustical materials is expressed as the average percentage absorption at the four frequencies which are representative of most household noises, these frequencies are 250, 500, 1000, and 2000 cycles/second

Sound Transmission Class: STC, single number which represents the minimum performance of a wall or floor at all frequencies, the higher the STC number, the more efficient the wall or floor will be in reducing sound transmission.

NRC : Noise Reduction Coefficient

The Noise Reduction Coefficient (NRC) is a scalar representation of the amount of sound energy absorbed upon striking a particular surface. An NRC of 0 indicates perfect reflection; an NRC of 1 indicates perfect absorption. In particular, it is the average of four sound absorption coefficients of the particular surface at frequencies of 250 Hz, 500 Hz, 1000 Hz, and 2000 Hz. These frequencies encompass the fundamental frequencies and first few overtones of typical human speech, and, therefore, the NRC provides a decent and simple quantification of how well the particular surface will absorb the human voice.

A more broad frequency range should be considered for applications such as music or controlling mechanical noise…Specifications for materials used in sound absorption commonly include an NRC for simplicity, in addition to more detailed frequency vs amplitude charts..

STC : Sound Transmission Class

Sound Transmission Class (STC) is an integer rating of how well a building partition attenuates airborne sound. In the USA, it is widely used to rate interior partitions, ceilings/floors, doors, windows and exterior wall configurations

The STC number is derived from sound attenuation values tested at sixteen standard frequencies from 125 Hz to 4000 Hz. These transmission-loss values are then plotted on a sound pressure level graph and the resulting curve is compared to a standard reference contour.

Indian Standards (IS CODE) for INSULATION

Forum Threads

Information on this site is purely for education (students / users) purpose. The materials used and displayed on the Sites, including text, photographs, graphics, illustrations and artwork, video, music and sound, and names, logos, IS Codes, are copyrighted items of respective owners. They are provided here just for reference / information. Their use here does not imply that you may use them for any purpose other than similar informational.

For your views and discussions Register in FDAchitects Forum …