- FORUM

- PROJECTS

- ABOUT US

- RESOURCES

- CONTACT US

- FORUM

- PROJECTS

- ABOUT US

- RESOURCES

- CONTACT US

Metal Hardware

Metal Hardware are metal products used in construction, such as: bolts, nails, screws (rough hardware); fittings such as latches, hinges, locks, etc. (finish hardware); tools.

Rough hardware : In building construction, hardware meant to be concealed, such as bolts, nails, screws, spikes, and other metal fittings.

Finish hardware : Hardware, such as hinges, locks, tower bolt, latches, etc., that has a finished appearance as well as a function, esp. that used with doors, windows, and cabinets; may be considered part of the decorative treatment of a room or building.

Hinges

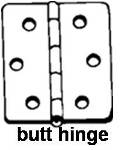

A movable joint used to attach, support, and turn a door (or cover) about a pivot; consists of two plates joined together by a pin which support the door and connect it to its frame, enabling it to swing open or closed.

Types of hinges :

- Double action hinge,

- butterfly hinge,

- butt hinge,

- dovetail hinge,

- gravity hinge,

- H-hinge,

- HL-hinge,

- pintle hinge,

- side hinge,

- strap hinge.

Gravity Hinge – A hinge that closes automatically as a result of the weight of a door to which it is attached.

HL hinge – A type of H-hinge that has a horizontal extension added to a foot of the hinge..

Pintle Hinge – A hinge that pivots about an upright pin or bolt.

Strap Hinge – A hinge fastened to a door and the adjacent wall by a long hinge.

Concealed hinge – Used for furniture doors (with or without self-closing feature, and with or without damping systems). They are made of two parts: One part is the hinge cup and the arm, the other part is the mounting plate.

Hinges

- Steel is a favorite for hinges of all types. It is relatively cheap, strong, and durable. Its evolution from outcast to ordinary,

- There are many steel alloys, but one in particular bears notice when it comes to hinges: stainless steel. This steel is composed of at least 10.5 chromium, which reacts with oxygen in the air to form a very thin film of chromium oxide on the surface of the steel.

- The discovery of this corrosion-proof metal is generally credited to Harry Brearley,

- Both brass and bronze are alloys of copper, which is one of the very first alloy humans were able to master.

- Brass, a mix of copper and zinc, was known to early civilizations, but did not enjoy the popularity of its bronze cousin largely because it was more difficult to produce. The Romans used it to a limited extent in coins and jewelry, but brass was not widely used until about the seventeenth century, when European woolmakers used brass pins in weaving. Brass has become even more popular since technology to reliably mass-produce it was introduced in the nineteenth century

Tower bolt / Barrel bolt

A door bolt which moves in a cylindrical casing; not driven by a key.

Latch

A simple fastening device having a latch bolt, but not a dead bolt; contains no provisions for locking with a key; usually openable from both sides.

Thumb Latch

Thumb latches are two-way latches and work as follows: on the outside (street-side) of the gate is a decorative plate with a thumb depressor. When you depress the thumb, a latch-arm on the inside of the gate lifts and allows the gate to be opened. Closing the gate, the latch-arm should hit the strike, rise up and fall into the catch on its own (a gravity latch).

Thumb latches can be installed only on in-swinging gates and are always double-sided. Some thumb latches are lockable, some are not.

Lift latch – for securing a door in a closed position, usually by means of a flat bar that falls into a catch when pressed by the thumb; for example, see Norfolk latch and Suffolk latch.

Suffolk latch – A type of thumb latch for doors; originally fabricated of iron wrought by hand in England. Attractive in appearance and available in many different designs; .=-

Norfolk latch – A type of thumb latch for a door that has a long metal plate behind the latch to protect the door finish; compare with Suffolk latch. .

Bolt Latch

some bolt latches might remind you of the old days, when you tied a string to a latch, tossed it over the gate, and called it good. Now there are a few spiffier versions of the old stand-by. We offer a nice selection of architectural bolt latches Usually bolt latches can be installed on either side of a gate. They are one way gate latches, operable only from the one side (although a string can get you access from the other side from the old style latch). Bolt latches are sometimes lockable, sometimes not. The lockable ones usually require an additional padlock.

Lever Latch

- Lever latches operate in the same way as a ring latch, but instead of a ring on each side, there’s a lever handle.

- Lever latches can be installed on both in-swinging and out-swinging gates. On out-swinging gates, the latch-arm side will be on the street-side of the gate. The best way to remember is that the latch-arm of the gate latch must be installed on the side that the gate opens toward.

- Lever latches can be either gravity-assisted or spring-loaded, depending on the manufacturer. Some lever latches are lockable; some are not.

Mortise Lock

A lock designed to be installed in a mortise rather than on a door’s surface. .

Hinges finishes

Finishes can also help hinges look like metals which are typically not suitable as a base metal for hinges, such as nickel. Nickel, a silvery metal, is rarely used in pure form. In fact, nickel was not even discovered to be a distinct element until 1751, when Axel Fredrik Cronstedt of Sweden accidentally extracted pure nickel, instead of copper, from the mineral niccolite.

- Brass versus brass plated.

Many hardware items are made of pure brass. Brass is a fairly soft metal, but it is weatherproof. It may be used inside or outside the house. It has to be used with care around salt water, however, because this can make it corrode. Brass plated is simply steel that has been coated with brass. It is not weather proof. - Bronze.

This is also available in pure form, and as such is weatherproof. Items made of it can be used inside or outside the house. It does not corrode; indeed, it is often used in marine applications. Bronze is also a very strong metal. - Bronze Plated.

Like brass plated, this is steel that is coated with bronze. Unlike pure bronze, however, it will not stand up to weather.

- Galvanized.

This is a special kind of finish applied to steel items. The galvanizing may be hot-dipped or coated-technically, electroplated. The hot dipped galvanizing is far the superior of the two. Both are weatherproof. Most outdoor items are galvanized. - Zinc or cadmium plated.

These terms are really synonymous. It is a wash coating that is given to hardware that makes them rust resistant but not rustproof. Galvanized items are far superior to ones with zinc or cadmium finishes.

- Blued.

This is hardly a finish but just a treatment given to items to keep them from rusting in the box while waiting to be sold. - Japanned.

This is a baked enamel finish, but only about as weather resistant as items that are blued. - Chrome plated.

This is a highly polished finish used on cabinet hardware and many plumbing items. It is highly resistant to corrosion and quite good-looking.

Information on this site is purely for education (students / users) purpose. The materials used and displayed on the Sites, including text, photographs, graphics, illustrations and artwork, video, music and sound, and names, logos, IS Codes, are copyrighted items of respective owners. They are provided here just for refrence/information.

For your views and discussions Register in FDAchitects Forum …