- FORUM

- PROJECTS

- ABOUT US

- RESOURCES

- CONTACT US

- FORUM

- PROJECTS

- ABOUT US

- RESOURCES

- CONTACT US

Ply and Board

PLY & Boards are sheet material which have been made from natural wood.

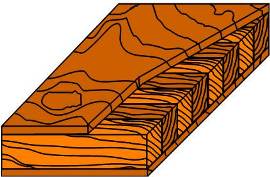

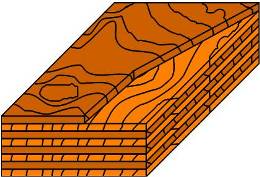

Ply and Board are produced because they have a number of qualities that make them better than solid timber in some situations. These include :Block Board – IS 1959-1990

This is built up with a core of softwood strips glued together and covered with a sheet of plywood on either side. Used as a building material and for furniture manufacture including fitted kitchens / bedrooms.

Partical Board / Chip Board

This is made up of small chips of wood glued together and formed into sheets by compression.

It is not as strong as plywood and block board but it is not expensive. Chipboard is often covered with a plastic laminate or wood veneer and used in furniture.

A large class of building board made form wood and particles and a binder, often faced with veneer, chipboard is made by binding phenolic resin or urea formaldehyde glue in the form of a 4 ft. wide board, length from 8-16 feet long with thicknesses ¼, 5/16/, 3/8, ½ , 5/8, and ¾ in.

Chipboards are used both from interior and exterior which include sheathing for walls, and roof, subflooring, fence paneling, and commercial exteriors and interiors.

Medium Density Fibreboard ( IS 12406-1988)

Medium Density Fibreboard is made from fine wood particles glued together under high pressure. The board is much stronger, denser and heavier than chipboard and is used to make better quality flat packed furniture. The surface is uninteresting and it can be veneered. Again it should never be used where there is moisture. Care must be taken when machining MDF as it is believed the glue in the dust can be carcinogenic (cause cancer).

Hard Board – IS 1658-1977

This is made from wood fibres that have been pulped.

The pulp is put under pressure until the fibres bond to produce a tough board that is smooth on one side and rough on the other.

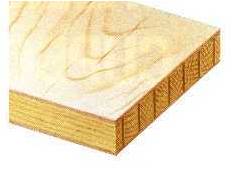

Plywood –IS 303-1989

Veneer plywood is made from thin layers of wood (veneers) that are glued together at 90 degrees to each other. This makes the sheets very strong and very stable.

Ply which is brown in colour, splinters easily and is used for general making such as drawer bottoms and cabinet backs. Usually plywood is not used where there is water or damp as it destroys the glue but there is a plywood made with waterproof glue and is often used in boat building – hence it’s name of Marine Ply.

All plywood comes in large sheets (1220 by 2440mm or 8 feet by 4 feet) and the thickness is usually 4, 6, 9, 12, 15, 18, 25mm but other sizes are available.

Qualities of Plywood

One of the main advantages of plywood is that It has a good strength across as width as along the panel. The more plies there are in a panel, the more nearly equal the strength in both directions will be.

The tendency to swell and shrink is neutralized to a large extent, because in plywood approximately half the wood grain runs in one direction and the other half at the right angles to it.

Plywood cannot be split in the plane of the panel because of its successive layers at right angles to another. Nails and screws can be driven very close to the edge of the panels without danger of splitting.

Plywood can be bent more easily than ordinary wood of the same thickness. The radius of curvature depends on the thickness of the panel an is limited by the strength of the outer piles in tension and by the strength of the inner piles in compression.

Information on this site is purely for education (students / users) purpose. The materials used and displayed on the Sites, including text, photographs, graphics, illustrations and artwork, video, music and sound, and names, logos, IS Codes, are copyrighted items of respective owners. They are provided here just for refrence/information.

For your views and discussions Register in FDAchitects Forum …